| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : EMT

Model Number : MG-4000

Certification : ISO9001,IATF16949

Place of Origin : China

MOQ : 1

Injection Pressure : 100 MPa

Mold Locking Force : 40000kN

Forming Process : Thixoforming

Warranty : 1 Year

Weight : 270000kg

Power Supply : 380V/50Hz

Energy Saving : Yes

Dimensions : Customer Required

Material : Magnesium Alloy

Operation Mode : Automatic

Control System : PLC

High-Performance 40000kN Semi-Solid Slurry Preparation Magnesium Alloy Die Casting Machine for Medical Product Manufacturing

| No. | DESCRIPTION | UNIT | MG4000 |

| 1 | Mold Locking Force | kN | 40000 |

| 2 | Mold Lock Stroke | mm | 1800 |

| 3 | Screw Diameter | mm | 170 |

| 4 | Injection Pressure | MPa | 100 |

| 5 | Theoretical Injection Volume | cm³ | 13618 |

| 6 | Systematic Operating Pressure | MPa | 16 |

| 7 | Ejector Force | kN | 950 |

| 8 | Machine’s Overall Dimension (L×W×H) | m | 19×7.2×6 |

The principle of the semi-solid injection molding equipment for magnesium alloys:

The magnesium alloy particle raw material enters the semi-solid slurry preparation tube (material tube) by negative pressure and gravity, and is hot melted in the material tube to form a solid-liquid two-phase mixture (semi-solid slurry) under the action of screw stirring and shearing. Due to the stirring and shearing, the solid phase becomes spherical and the slurry has good fluidity. In this state, the slurry is high-speed pressed into the mold for molding, cooled and shaped, and the integrated magnesium alloy product can be obtained.

Applied Industry:3C Electronic Products

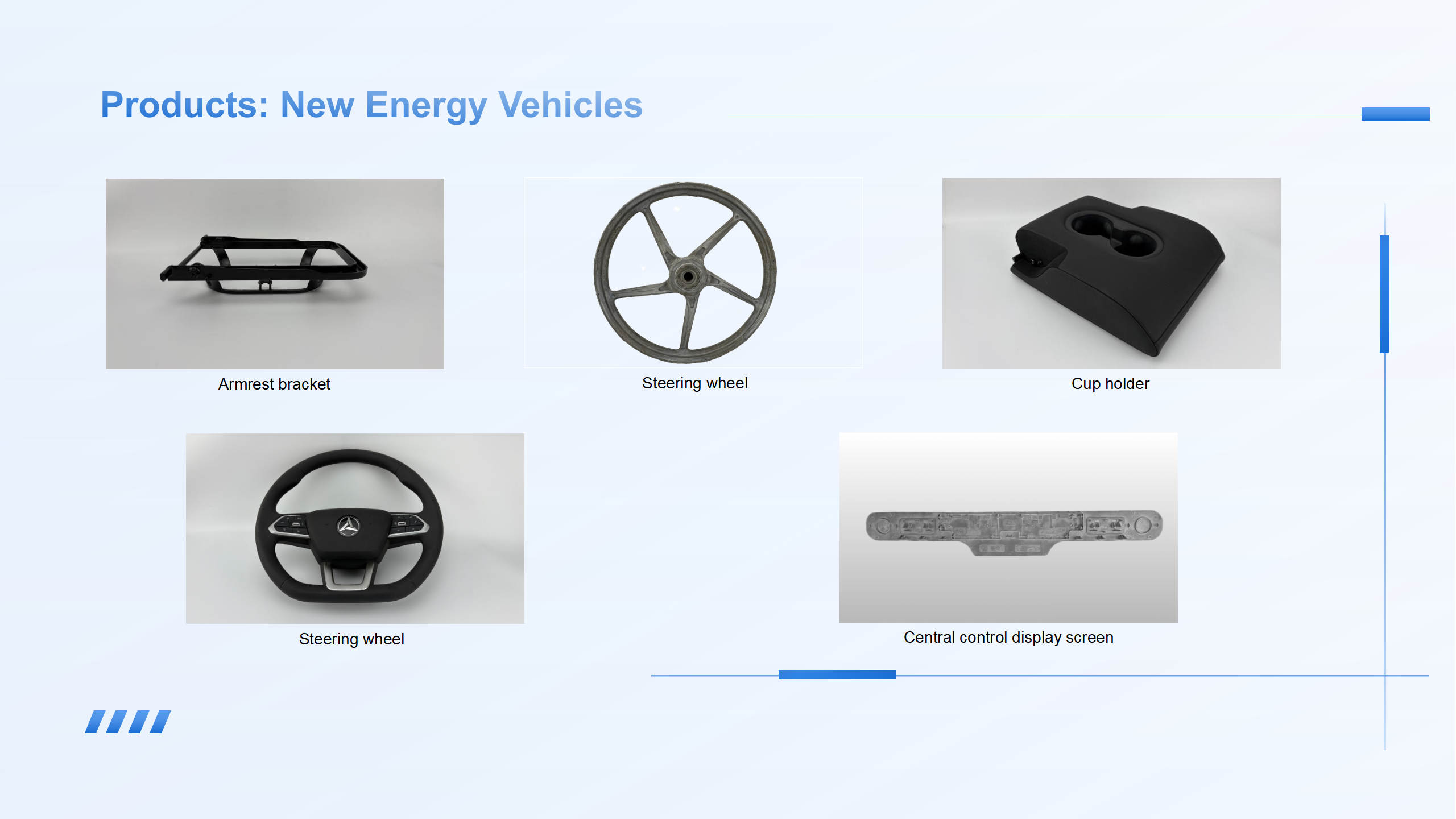

Applied Industry:New Energy Vehicles

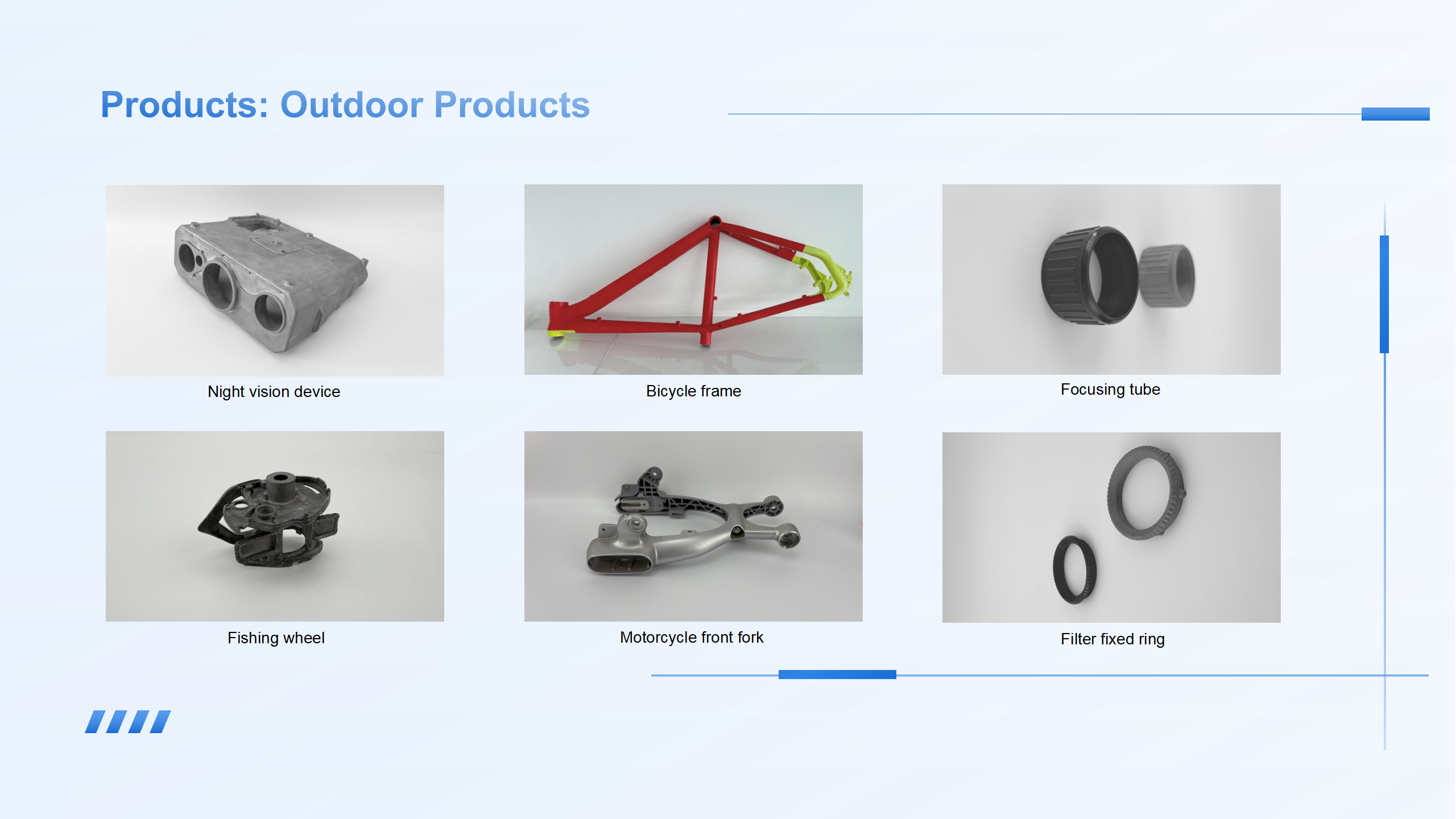

Applied Industry:Outdoor Products

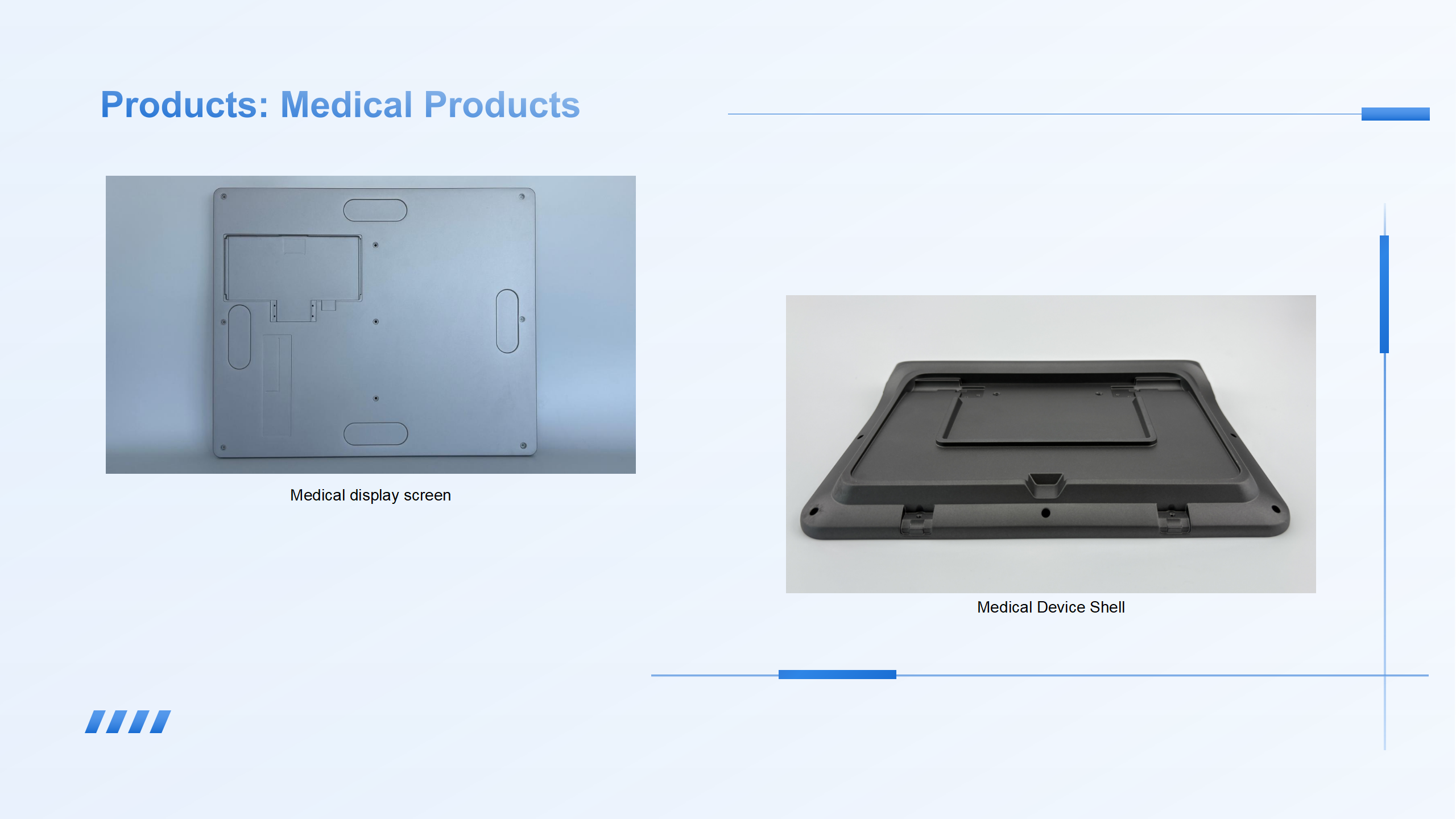

Applied Industry:Medical Products

|

|

High Performance 40000kn Semi Solid Slurry Preparation Magnesium Alloy Die Casting Machine For Medical Product Manufacturing Images |